Series 3000

3.Custom Features

Date : 2013-09-20 16:30|

Materials of Construction |

| ??Standard Construction |

| G-235 mill galvanized steel is the heaviest commercially available galvanized steel, universally recognized for its strength and corrosion resistance. To assure long-life, a G-235 mill galvanized steel frame, casing panels and louvers is used as the standard material of construction. The structural integrity of the unit is provided by its strong steel frame. Series 3000 standard construction has been seismically verified by shake table testing in an independent laboratory up to an SDS of 1.40g and can withstand wind loads of up to 60 psf, proving its frame construction is designed for extreme durability. With proper maintenance and water treatment, G-235 galvanized steel will provide an excellent service life under the operating conditions normally encountered in comfort cooling and industrial applications. |

| ??Stainless Steel (Option) |

|

| ??Basinless Unit Construction (Option) |

|

| ??Seismic/Wind Upgraded Structure(Option) |

| Select steel panels and structural members are upgraded for higher seismic and wind load applications. An upgraded Series 3000 is certified to withstand up to an SDS of 3.10g and wind loads of 82 psf. All BAC upgraded units are shake table tested by an independent laboratory to certify the most accurate seismic ratings ensuring that the unit will remain operable following a seismic event. |

| ??Standard Steel Casing Panels and Louvers |

| Used with BAC’s durable frame construction, galvanized steel casing panels and louvers offer a more durable corrosion resistant unit. |

| ? Stainless Steel/FRP Casing Panels and Louvers (Option) |

| Stainless steel/FRP casing panels and louvers are available in G-235 galvanized steel construction. |

|

Drive System Options |

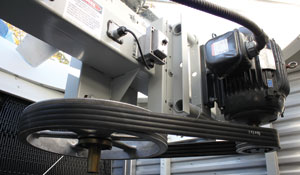

| ? Standard BALTIDRIVE? Power Train |

| The BALTIDRIVE? Power Train utilizes special corrosion resistant materials of construction and state-of-the-art technology to ensure ease of maintenance and reliable year-round performance. This BAC engineered drive system consists of a specially designed powerband and two cast aluminum sheaves located at minimal shaft centerline distances to maximize belt life. As compared to a gear drive system, this specially engineered belt drive system provides many advantages. The BALTIDRIVE?Power Train requires only periodic inspection of components and belt tensioning, which is simple with a single nut adjustment, and requires less downtime. Only fan bearing lubrication is required for routine maintenance. Belt drive systems also have the added advantage of being suitable for variable frequency drive (VFD) applications without requiring expensive optional accessories. |

|

|

BALTIDRIVE? Power Train Fan System |

| ??BALTIGUARD? Fan System (Option) |

| The BALTIGUARD? Fan System consists of two standard singles-peed fan motor and drive assemblies. One drive assembly is sized for full speed and load, and the other is sized approximately 2/3 speed and consumes only 1/3 the design horsepower. This configuration provides the reserve capability of a standby motor in the event of failure. As a minimum, approximately 70% capacity will be available from the low horsepower motor, even on a design wet-bulb day. Controls and wiring are the same as those required for a two-speed, two-winding motor. Redundant motors are available by increasing the size of the standby fan motor of the BALTIGUARD? Fan System to the size of the main motor. This provides 100% motor redundancy and the greatest level of reliability. |

? |

| BALTIGUARD? Fan System

|

| ??Gear Drive System, Close-Coupled Motor (Option, Standard on S3E-1222-14T, S3E-1424-12T, S3E-1424-13T, and S3E-1424-14T) |

| A gear drive system is available as a fan drive option on the Series 3000. Both the gear drive and couplings are selected with a 2.0 service factor. Gear construction includes a nickel-alloy steel shaft, casehardened gears, self lubrication, and a single piece, gray iron housing. This drive system ships completely installed and aligned. |

| ??Gear Drive System, Externally Mounted Motor (Option) |

| A gear drive system with a TEFC motor mounted outside the airstream is also available on the Series 3000. A non-corrosive carbon-fiber composite drive shaft with stainless steel hubs is selected with a 2.0 service factor. The motor and drive shaft ship separately for easy field installation. |

|

Multi-Cell Unit Options |

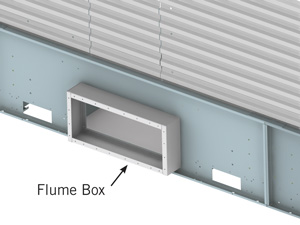

| ??Flume Box – Standard on all Multi-Cell Units |

| A flume box is provided as standard for multi-cell units to balance the water level in the cold water basins. |

|

| ??Equalizer (Option) |

| Equalizer connections are available as an option for multi-cell cooling towers in lieu of a flume box. Use of an equalizer allows for easy isolation of a cell for winter operation, maintenance, or inspection while continuing system operation. |

| Water Distribution System |

| ??Standard Top Inlet Connections |

| The Series 3000 comes standard with top inlet connections to each of the hot water basins. Hot water basin covers matching the unit material of construction come in easy to handle sections for easy access and inspection of the distribution system. The use of gravity distribution minimizes pump head requirements and allows for maintenance during unit operation. BAC’s patented non-clog nozzles ensure even flow over the fill area and are simple to remove for maintenance. |

| ??EASY CONNECT? Piping Arrangement (Option) |

| The EASY CONNECT? Piping Arrangement simplifies water inlet piping on the Series 3000 by automatically balancing the flow within each cell, eliminating the need for flow balancing valves. A single water inlet connection, located on the side or bottom of each unit, eliminates the need for overhead piping and piping supports. It reduces installation costs and reduces potential for errors during field piping fabrication. |

|

|

EASY CONNECT? Piping Arrangement |

| ??Standard Weir Dams |

| Reducing water flow through a unit below the recommended level may potentially create uneven water distribution through the heat transfer section, causing scale build up, splash out/drift, and icing. To successfully modulate the water flow while avoiding potential complications, weir dams may be installed in the hot water basin. With a weir dam, the hot water basin can accommodate a flow range of 50% to 100% of the design flow./td> |

|

|

Weir Dams |

|

Fill |

| ??Standard Fill |

| Standard fill can be used in applications with entering water temperature up to 130°F (54.4°C). The fill and drift eliminators are formed from self-extinguishing PVC having a flame spread rating of 5 per ASTM E84. |

| ??High Temperature Fill (Option) |

| An optional high temperature fill material is available which increases the maximum allowable entering water temperature to 140°F (60°C). |

|

??Capacity Enhancement |

|

The need to enhance the capacity of a unit may be necessary when layout is restricted or if capacity requirements have increased and exceed an existing unit’s capabilities. By enhancing the capacity of a unit, it may be possible to use a smaller foot print while still meeting thermal requirements of the installation. |

| ??Velocity Recovery (VR) Stacks (Option) |

| A VR stack is a conical fan cowl extension that reduces the discharge pressure the fan has to work against, allowing the fan to move more air for the same energy input. By moving more air through the same unit, the cooling capacity is increased without increasing horsepower or footprint. Effectively, the amount of energy required for each ton of cooling capacity is reduced. VR stacks are CTI certified and can be configured during initial unit purchase to reduce energy requirements or through the aftermarket to increase capacity. |

|

|

Velocity Recovery Stacks |

| Shipping and Rigging |

| ??Standard Rigging Guides |

| Rigging guides allow for the upper and lower section of units with a two piece rig to align and engage. The guides ensure proper placement of the top section for multi-cell installations, making rigging much simpler and reducing the time required. This is especially critical during multi-cell installations when units are rigged side-by-side. |

| ??Knockdown Units (Option) |

| Knockdown units are available for jobs where access to the cooling tower location is limited by elevators, doorways, or similar obstacles, where lifting methods impose very strict weight limits, or where the shipping cost of a fully assembled tower is excessive. All materials of construction and design features are the same as those of a factory assembled unit. Welded Type 304 stainless steel cold water basins are excluded due to the need for in-plant assembly. |

|

Air Intake |

| ??Standard Louvers |

| Air intake louvers matching the material of construction of the unit casing panels are standard. Scale formation and icing on the louvers and fill sheets can damage the fill and reduce thermal performance. The Series 3000 louvers are specially designed with greater spacing between louvers (12”) and are completely separate from the fill section. This reduces scale and ice accumulation and allows for unobstructed air flow through the unit. |

| ??Combined Inlet Shields (CIS) (Option) |

| The Combined Inlet Shields’ (CIS) bent flow path blocks sunlight from the cold water basin and fill section and acts as a screen to prevent debris from entering the unit. These benefits result in a significant reduction in algae growth, debris accumulation, and scale build-up. CIS are constructed from corrosion and UV resistant PVC, are CTI certified, and are installed in easy to handle sections that are separate from the fill section to facilitate removal, inspection, and replacement. The use of CIS results in lower maintenance costs and ease of maintenance over the life of the unit. |

| ??Air Intake Screens (Option) |

| 1” x 1” wire mesh screens are available factory-installed over the air intake louvers to prevent debris from entering the tower and are CTI certified. |

|

Sound Options |

| ??Standard Fan |

| The fan provided for all Series 3000 Cooling Towers is selected to optimize low sound levels and maximize thermal performance. |

| ??Low Sound Fan (Option) |

| The Low Sound Fan option reduces sound up to 9 dBA. Adding a high solidity fan decreases fan speeds, which proportionally decreases sound levels. The thermal performance with the Low Sound Fan has been certified in accordance with CTI Standard STD-201. |

| ??Whisper Quiet Fan (Option) |

| For the most extreme sound limitations, BAC’s Whisper Quiet Fan reduces sound up to 19 dBA. The fiberglass reinforced polyester (FRP) fan blades have blade leading edge protection as standard. These chemical resistant, non-corrosive fans require minimal maintenance, making them well suited for use in cooling tower applications. |

| ??Sound Attenuation (Option) |

| Factory designed, tested, and rated sound attenuation options are available for both the air intake and discharge. Consult your local BAC Representative regarding available options. |