Reduced Energy Consumption

|

- - Most efficient cooling tower in the industry

- - Up to a 16% increase in capacity

- - Exceeds ASHRAE 90.1-2013 efficiency requirements

|

|

|

|

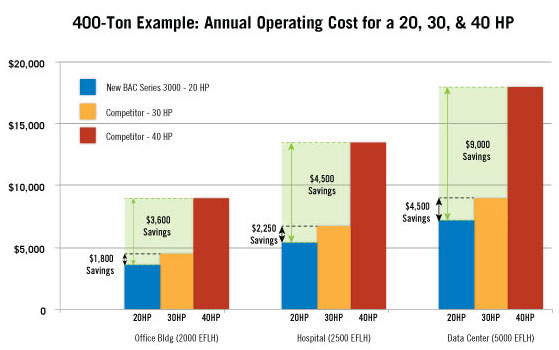

Energy Cost Savings Based on a 400-Ton System ($0.12 kWH)

|

|

400-Ton Example

|

Series 3000

|

Competition

|

Competition

|

|

Fan (KW)

|

15

|

22

|

30

|

|

Footprint (mm)

|

2588 x 5481 x 3654

|

2588 x 5481 x 3654

|

2588 x 5481 x 3654

|

|

Capacity (NT)

|

400

|

386

|

423

|

|

|

More Selection Flexibility

|

- - 31 new models

- - 3 new box sizes

- -?69 XE-Series 3000 Cooling Tower?models are available in a full array of box sizes

|

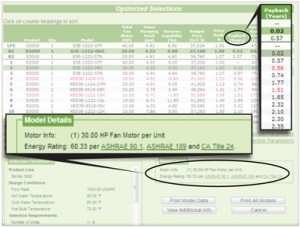

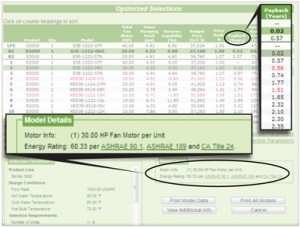

Enhanced Payback Analysis

|

- - Provides alternative selections based on energy savings and minimum payback

- - User-defined life-cycle cost inputs

- - XE-Series models featured in?selection program

|

? |

| ?Enhanced Product Selection Software |

Low Environmental Impact

|

|

|

- ? a. Meets or exceeds ASHRAE Standard 90.1 energy efficiency requirements

- ? b. Premium efficient/inverter duty fan motors

- ? c. Gravity distribution system with low pump head requirements

|

- - Sound Reduction Options

|

- ? a. Standard fan is high efficiency and low sound

- ? b. ?For further reduced sound levels, Low Sound Fans, Whisper Quiet Fans, and sound attenuation are available options

|

Durable Construction

|

- - Meets wind and seismic requirements of the International Building Code (IBC)

- - Designed to withstand wind loads up to 60 psf, upgraded units designed to withstand 82 psf

- - Seismically verified through dynamic shake table testing up to a SDSof 3.10g

|

|

|

Shake Table Tested

|

- - Listed on California’s Office of Statewide Health Planning and Development (OSHPD) pre-approved equipment list

- - Casing panels constructed of corrosion resistant FRP with rigid frame construction

- - Enhanced longevity with a variety of durable materials of construction

|

? |

| ?Durable Frame Construction |

Reliable Year-Round Operation

|

| - Separate air intake louvers for easy visual inspection of the air-water interface |

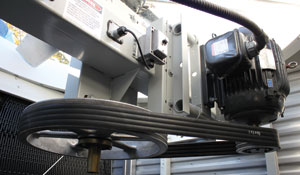

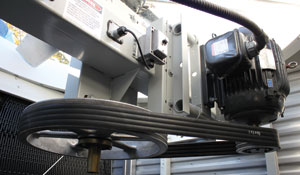

- BALTIDRIVE??Power Train Fan System

- ? a. BAC specified motor brand

- ? b. Corrosion resistant cast aluminum sheaves with specially designed powerband belts

- ? c. Cooling tower duty motors designed for hostile environments

|

?  |

| ?BALTIDRIVE? Power Train Fan System |

Easy Maintenance

|

| - Crossflow configuration provides direct access for easy maintenance |

| - BALTIDRIVE??Power Train uses state-of-the-art technology to ease maintenance |

| - Patented hygienic cold water basin is sloped at the air intakes to eliminate stagnant water and reduce biological growth |

| - Fill surface is elevated above the sloped cold water basin floor to facilitate flushing of dirt and debris |

| - Hinged access doors provide easy access to the cold water basin and fan drive system |

| - Combined inlet shields block sunlight, reducing the potential for algae growth in the cold water basin (option) |

| - Louver face platforms, internal service platforms, and internal walkways simplify maintenance (option) |

?  |

|

?Louver Face Platforms

|

Easy Installation

|

|

| Flexible Piping Arrangement

|

- - Rigging guides ensure?proper alignment and reduce rigging time- Flexible inlet/outlet piping connection locations ensure proper fit for any applications

|

- - Adaptable steel support configuration options, utilizing pre-existing support steel

|

- - Knockdown units available for field assembly

|

- - EASY CONNECT? ?Piping Arrangement reduces installation costs by eliminating overhead piping and piping support requirements (option)

- - Basinless construction ability, ideal for installations using a common sump for multiple tower cells (option)

|

|

|

|

|

|

|

|

|

|